Diffusion dialysis

- Products

- FORBLUE SELEMION™

- Diffusion dialysis

Using SELEMIONTM Ion-Exchange Membranes for Diffusion Dialysis

This process separates metal ions from acids, thereby helping to stabilize production efficiency.

- Waste acids containing metal ions that are discharged during metal surface treatment and other such processes are treated to separate and recover free acids.

- Acids thus recovered and be recycled and reused in surface treatment and other processes.

- It therefore does not require a power source to move ions.

This results in lower running costs. The equipment is also simple.

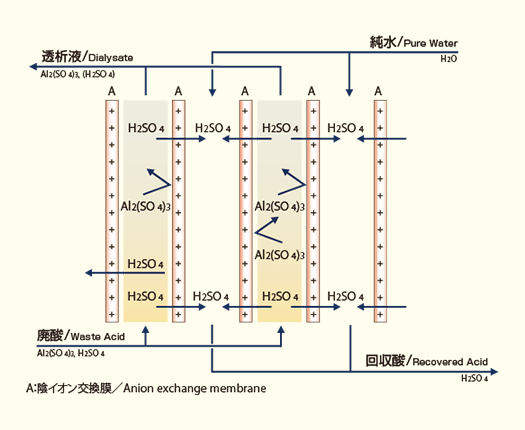

Principle of diffusion dialysis

Multiple anion-exchange membranes are laminated into a stack, with spacers in between the membranes. One side of the laminated anion exchange membranes is fed with waste acid, and the opposite side with water as a counter-stream. Any concentration difference generated via the anion exchange membrane causes acids to diffuse and move from the waste acid side to the water side (the recovered acid side). Metal ions having large multivalent cations, however, cannot pass through the anion exchange membrane and remain on the dialysate side. Free acids can thus be separated and recovered from metal ions.

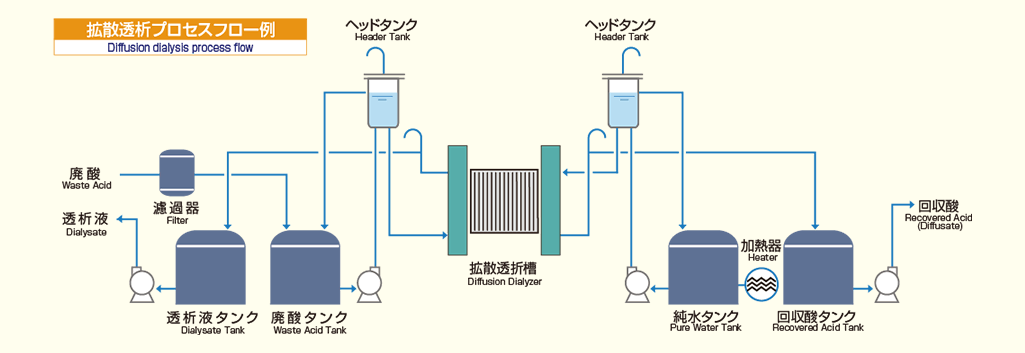

Process flowchart of diffusion dialysis

Unlike electrodialysis, diffusion dialysis feeds the diffusion dialyzer from the head tank with solution by using the difference in solution level. This process separates metal ions from acids without circulating the solution.

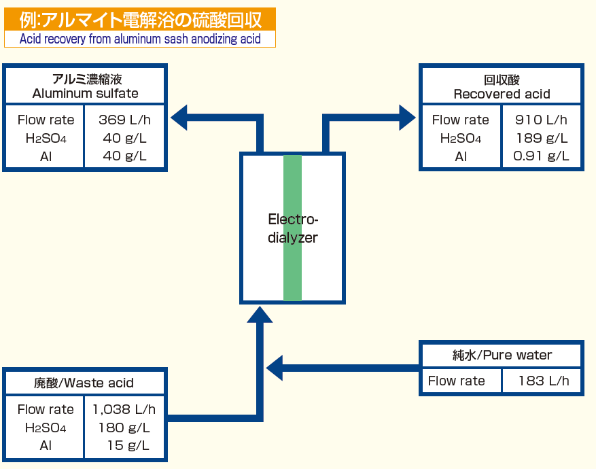

Differences between electrolysis acid recovery and diffusion dialysis acid recovery

Advantages of electrodialysis acid recovery

- Concentrates and recovers free acids.

- Reduces the volume of waste acid.

Advantages of diffusion dialysis acid recovery

- Requires no electricity, resulting in lower running costs.

- The system's simple process flow makes it operate and maintain.

Applications of acid recovery by diffusion dialysis

Click here for an applicable areas.

- Aluminum sash anodizing acid

- Aluminum foil etching acid from electrolytic capacitor

- Steel surface treatment acid

- Stainless steel surface treatment acid

- Noble metal industry

- Various metal industries