What is FORBLUE sunsep™?

- Products

- FORBLUE sunsep™

- What is FORBLUE sunsep™?

The FORBLUE™ sunsep™ is a series of membrane dryers/humidifiers based on hollow fibers made from fluorine-based ion exchange resins developed by AGC .

Product features

Allows only moisture to permeate through the membrane rapidly

Hardly affects the gas component to be humidified or dehumidified.

Capable of both humidification and dehumidification

Moves water vapor from higher-humidity gas to lower-humidity gas (water can be used as well).

Ecological value

Because the driving force is the humidity differential between gases, no energy input is required.

-

AGC FORBLUE sunsep Demonstration of gas dehumidification

sunsepTM: How it works

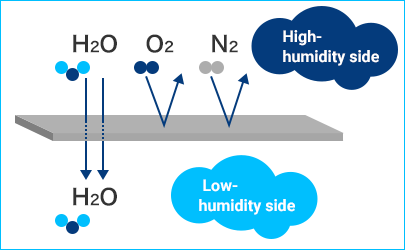

The hollow fibers in the FORBLUE sunsep™ unit tend to equalize the humidity (moisture pressure) differential between the air (gas) inside the hollow fiber membrane and the air (gas) outside it, by moving moisture from the higher-humidity side to the lower-humidity side.

Because the membrane is nonporous, little more than moisture vapor can pass through it.

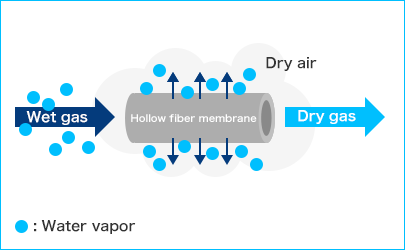

Principle of Dehumidification

When dry air (gas) is supplied to the inside of the membrane and moist air (gas) is supplied outside the membrane, the moisture moves through the membrane to the drier air (gas) inside, producing humidified air (gas).

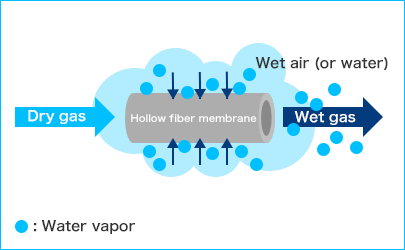

Principle of Humidification

These membranes flow dry air (gas) in and flow wet air (gas) or water out. Contrary to dehumidification, the membranes move steam from outside to inside. As a result, humidified air (gas) is obtained.

Click here for more information on humidification and other applications.

OEM / Custom Manufacturing

We can manufacture customized products to meet your form and application requirements.Click here for more information.

What is a nonporous membrane?

Other companies use porous membranes to remove moisture, but this allows substances that are smaller than the pores to escape along with the moisture.FORBLUE sunsepTM uses a nonporous membrane to ensure that hardly any gas other than moisture passes through.

A cross sectional photo of a hollow fiber membrane, enlarged by about 25,000 times. It shows that the nonporous membrane has no pores.