Dehumidification

- Products

- FORBLUE sunsep™

- Dehumidification

For more than 30 years since their release, FORBLUE sunsep™ membrane air dryers have been used in a variety of applications requiring the drying or dehumidification of air or gas.

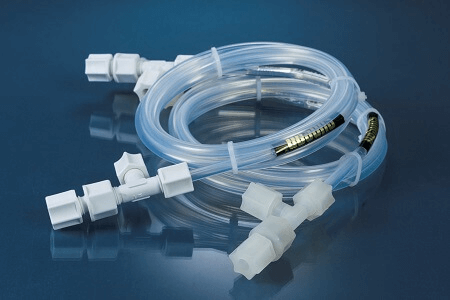

For compressed air dehumidification: SWB / C / F series

Small, lightweight sunsep™ units can be mounted anywhere on compressed air lines, in any position. The appropriate model can be selected from a broad range of products according to the user's processing and space requirements.

-

-

AGC FORBLUE sunsep Demonstration of gas dehumidification

Applications

- Dehumidification of compressed air for industrial use

- Pneumatic equipment protection from water troubles

- Generation of a dry atmosphere

Click here for a table of products and more information.

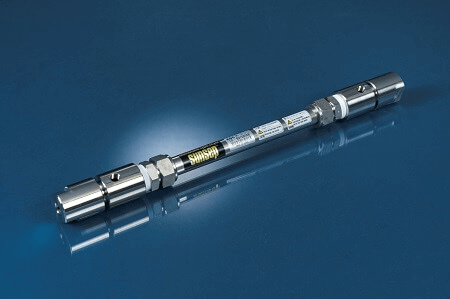

For sample gas dehumidification : SWG series

sunsep™ quickly absorbs and permeates only airborne moisture and releases it outside the membrane. For this reason it can dehumidify sample gas without affecting the balance of its components. sunsep™ hollow fiber membranes are made from fluorinated ion-exchange resins, and can therefore be used to dehumidify corrosive gases.

Applications

- Dehumidification of flue gas, atmosphere, and other gas for environmental analysis

- Dehumidification of human breath and other sample gases for various research purposes

- Sample gas dehumidification for sulfur analyzers, chromatographs, etc.

Click here for a table of products and more information.

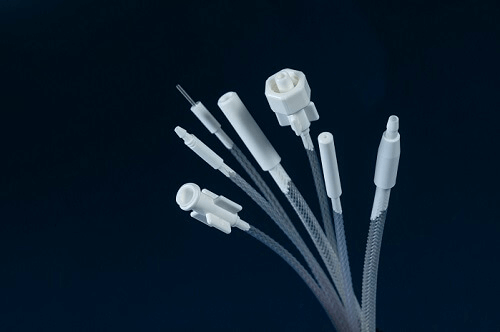

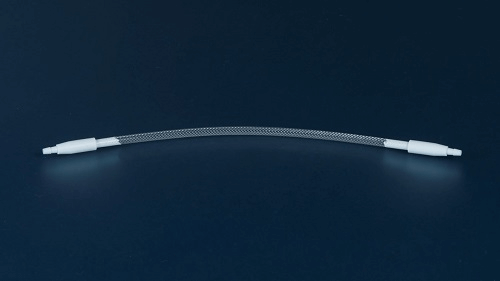

SWT Series: for the dehumidification of very low flow-rate gases

Even a single sunsep hollow fiber membrane functions effectively as a dryer. The unique SWT series dryers consist of a single braid-reinforced hollow fiber membrane. With this product, it is possible to dehumidify/condition gases at flow rates under 100ml/min.

Applications:

- Dehumidification/conditioning of very low flow-rate gases (10~500 ml/min (ANR)).

For a list of SWT products and data, click here.